IC packaging tube mainly used for packaging and shipping electronic components, module power supply, precision switches, semiconductors, connectors, and other components. The packaging tube has precise size, is anti-static, difficult to be stuck, no impurities, Non-thorn, high transparency, good elasticity, high wear resistance, product pressure resistance, strong drop resistance, high toughness, not easy to deform, hard texture, good anti-drying performance, strong corrosion-resistance, high mechanical strength, durability, etc. It is more suitable for automated production line use.

Anti Static Plastic IC Tubes can be made of plastics of various materials such as PVC, PS, PET, PC, ABS, etc. The packaging tubes of different materials will have different performances. The characteristics of various materials and their packaging tubes are described in detail below:

1. PVC, the full name is polyvinyl chloride. The material has the advantages of non-flammability, high strength, good flexibility, easy molding, not being brittle, excellent geometric stability, non-toxic and non-polluting, and long storage time.

Advantages of PVC tubes:

1). Easy to shape and easy to process.

2). The hardness is good, and the pipe wall is not easy to be broken during long-distance transportation so that the electronic component products can be better protected.

3). The price is low, significantly saving production costs.

Disadvantages of PVC packaging tubes:

1). Does not meet the halogen-free requirements.

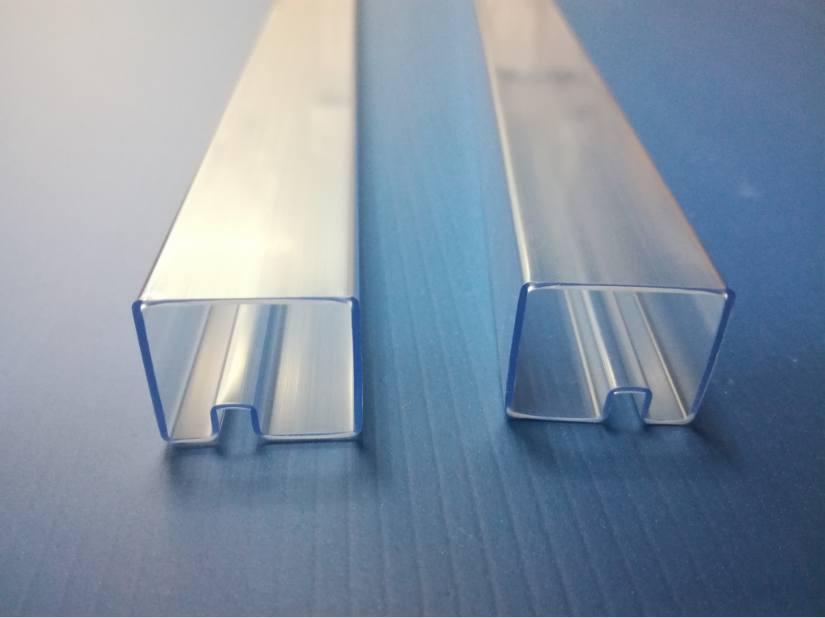

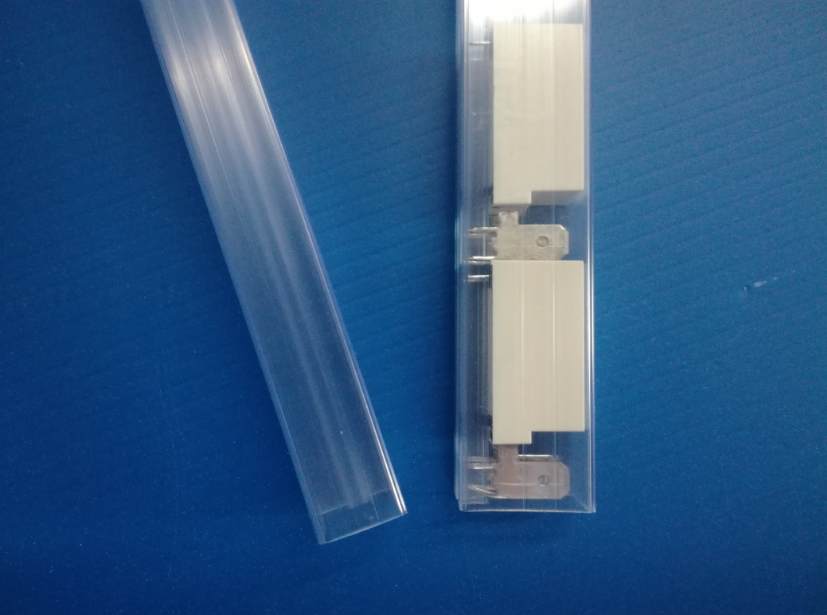

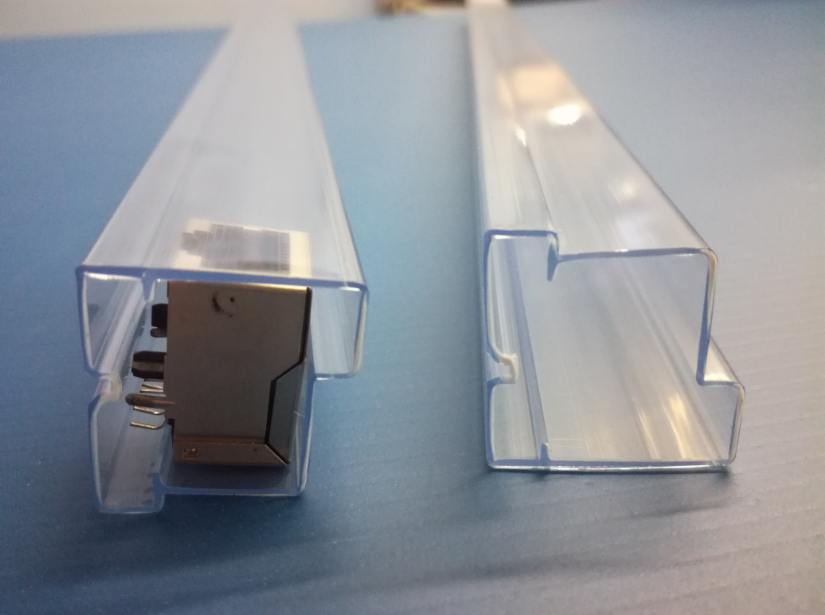

IC tubes sample (PVC material)

IC tubes sample (PVC material)

2. HIPS is an abbreviation for impact-resistant polystyrene, an impact-resistant polystyrene product produced by adding polybutadiene rubber particles to polystyrene. HIPS has the characteristics of easy processing, good performance, low price, and environmental protection. However, the gloss of the material is poor, the impact strength is low, the product is brittle, and its all-around performance is lower than that of PVC and ABS.

Advantages of PS packaging tube

1). Easy to form, green, and environmentally friendly, in line with halogen-free standards and Sony SS-00259 standard.

Disadvantages of PS packaging tube

1). If the thickness is the same, the PS packaging tube is more brittle than the PVC packaging tube. Therefore, when designing the electronic component packaging tube, if the customer chooses the PS material, we will generally thicken the pipe wall by about 1MM. Guarantee safety during transportation. In addition, we also need to consider whether the nozzle will burst when the PS packaging tube is cut during production.

2). The price of the PS packaging tube is much higher than that of the PVC packaging tube. Most electronic component manufacturers choose to use PVC packaging tubes to automate packaging.

IC packaging tube sample (PS material)

3. ABS plastic is a terpolymer of acrylonitrile (A)-butadiene (B)-styrene (S). It combines the properties of three components:

- Acrylonitrile has high hardness and strength, heat resistance, and corrosion resistance.

- Butadiene has impact resistance and toughness.

- Styrene has high surface gloss and easy coloration and is easy to process.

Therefore, ABS plastic has high strength, is lightweight, has a large surface hardness, is very smooth, easy to clean, dimensionally stable, and environmentally friendly. ABS is susceptible to stress cracking due to solvent, poor weather resistance, and sunlight, discoloration, and brittleness.

Advantages of ABS packaging tube

1). easy to process, easy to color, spray;

2). has high impact, high heat, flame retardant, enhanced, transparent, and other levels.

3). the fluidity is slightly worse than HIPS, better than PC, and has good flexibility.

Disadvantages of ABS packaging tubes

1). It is susceptible to solvent stress cracking and poor pressure resistance

2). It is affected by temperature and is susceptible to sunlight, discoloration, and brittleness.

IC packaging tube sample (ABS material)

Extended reading “What are the factors that affect the appearance of IC shipping tubes?”

4. PET is an amorphous copolyester. Its products are highly transparent, excellent in impact resistance, challenging, good in gloss, non-white under pressure, good in low-temperature resistance, easy to form and post-process, as Environmentally friendly materials that meet FDA standards for food contact. PETG has a low heat distortion temperature and poor drying performance.

Advantages of PET anti-static tubes

1). lighter texture and high transparency;

2). impact resistance is not easy to break, and other characteristics, easy to transport.

Disadvantages of PET packaging tubes

1). The price is slightly higher than the packaging tube of PC material

2). Easy to carry static electricity

IC packaging tube sample (PET material)

5. PC is the abbreviation of polycarbonate. It is an amorphous thermoplastic resin with excellent comprehensive properties. It has excellent electrical insulation, elongation, dimensional stability and chemical resistance, high strength, and heat resistance. And cold resistance; also has the advantages of self-extinguishing, flame retardant, non-toxic, colorable, and so on.

Advantages of PC packaging tubes

1). transparent and with a high gloss on the surface;

2). high stability, good electrical insulation, easy to color.

Disadvantages of PC packaging tubes:

1). High melt viscosity

2). Extremely sensitive to moisture, prone to internal stress cracking

IC packaging tube sample (PC material)

Extended reading “How to identify quality IC Shipping Tube guide