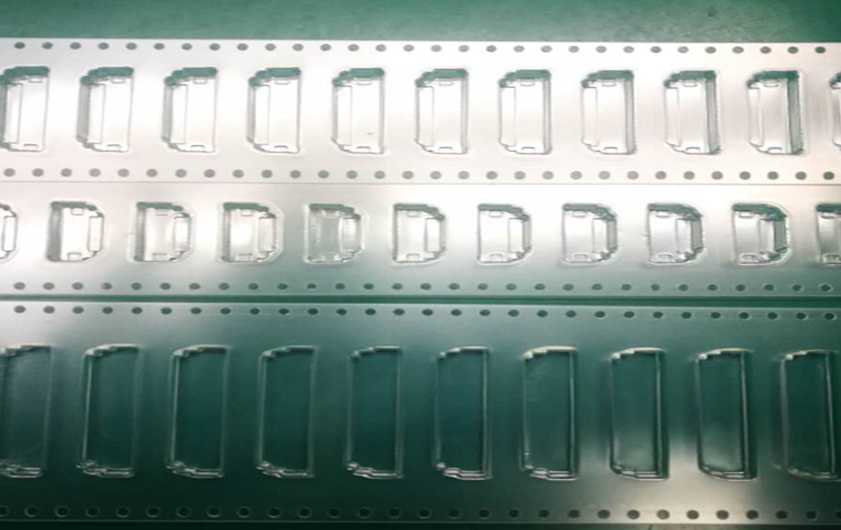

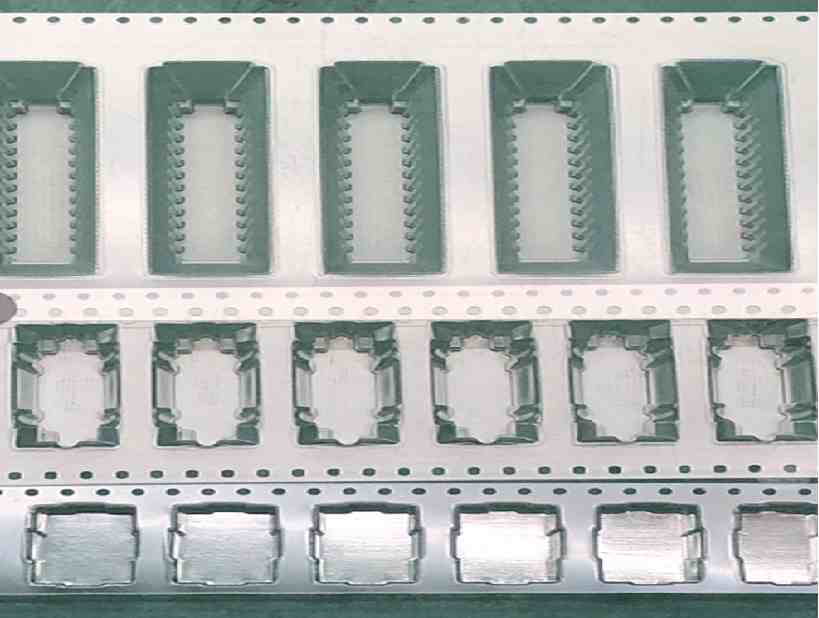

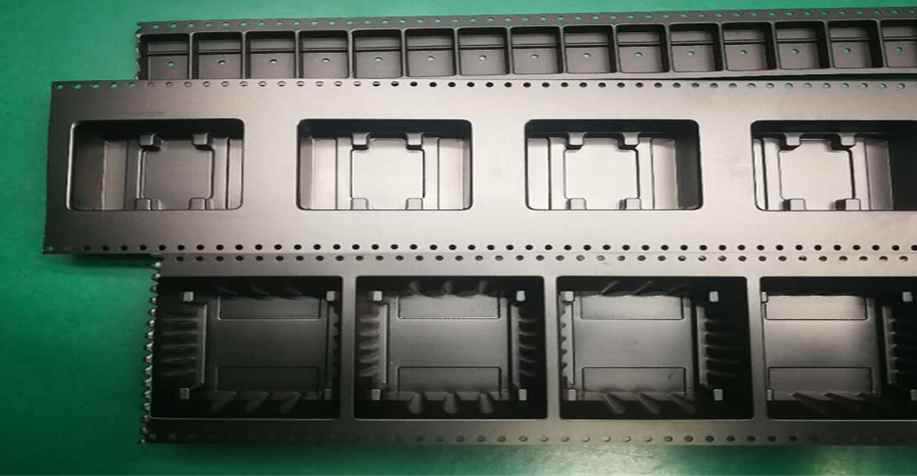

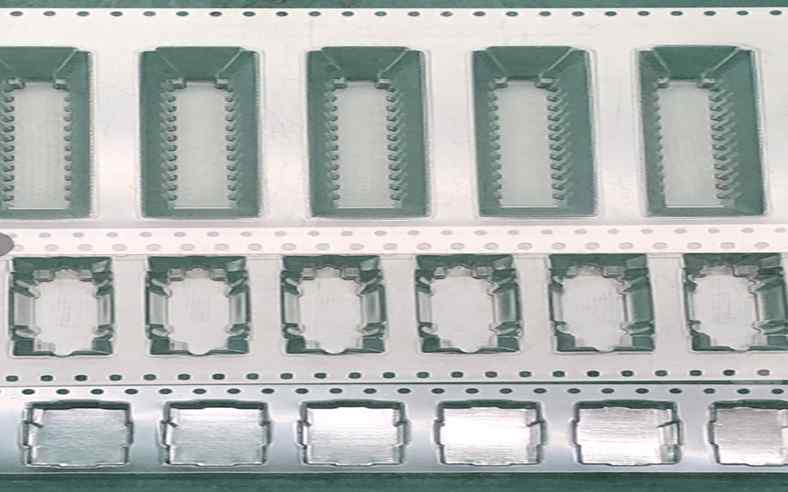

Embossed carrier tape provides protection for various kinds of components from physical and ESD damage during shipping and storage. Sewate is an expert in matching the correct material and thickness for your particular application.

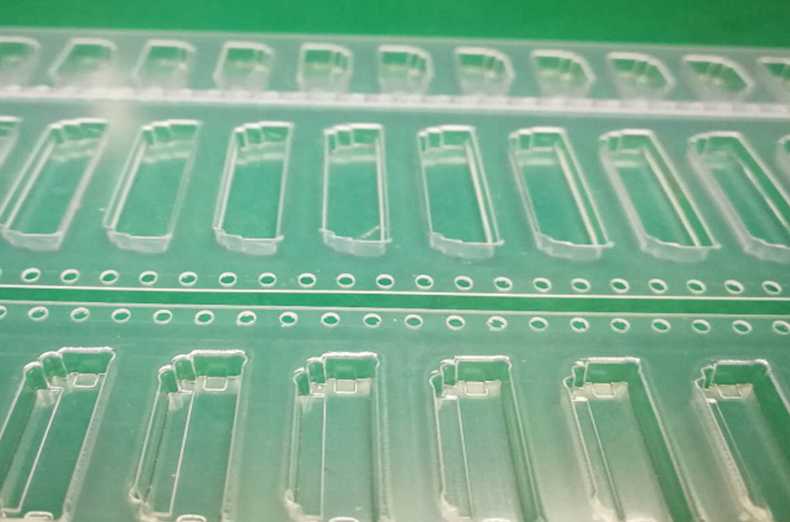

Carrier Tape refers to a tape-shaped product used in the field of electronic product packaging. It has a specific thickness and is equidistantly distributed along its length with Cavities (also known as pockets) for holding electronic components. and positioning cavities for index positioning.

The carrier tape is mainly used in the electronic component mounting industry. The carrier tape is used with the cover tape (upper tape) to carry the electronic components such as resistors, capacitors, transistors, diodes, and the like in the carrier tape pocket, and the closed tape is formed by sealing the cover tape over the carrier tape. Protect electronic components from contamination and damage during transportation. When the electronic components are placed, the cover tape is peeled off. The automatic placement device sequentially takes out the components in the pocket through the precise positioning of the tape index cavities. It mounts them on the integrated circuit board (PCB board).

Classified by width:

The carrier tape is also divided into different widths depending on the electronic components carried by the package. Common widths are 8mm, 12mm, 16mm, 24mm, 32mm, 44m, 56mm, etc. With the development of the electronic market, the chip has a smaller and smaller trend, and the carrier tape has also developed in a precise direction. Currently, there is a carrier tape supply of 4 mm width on the market.

Classified by function:

Some sophisticated electronic components have precise requirements for the anti-static level of the carrier tape. According to the anti static level, the carrier tape can be divided into conductive, anti static type (static dissipative type), and unconducive.

Classified by the molding characteristics of the pocket:

An embossed carrier tape and a punched carrier tape. The embossed carrier tape refers to the partial stretching of the carrier tape material by the method of imprinting or blistering the mold to form a pocket of a concave shape. The carrier tape can be formed into pockets of different sizes according to specific needs to accommodate the loading. The size of the electronic components. Stamping tape refers to the formation of penetrating or semi-transparent pockets by die-cutting. The thickness of the electronic components that can be held by the carrier tape is limited by the thickness of the carrier tape itself, and generally can only be used to package smaller components.

Classified by carrier material:

The material of the carrier tape mainly includes two types: plastic (polymer) and paper. The embossed carrier tape is mainly composed of plastic materials. The mainstream in the market is PC (Polycarbonate, polycarbonate) carrier tape, PS (Polystyrene, polystyrene) and ABS (acrylonitrile-butadiene-styrene copolymer resin). Belts, in addition to a small amount of carrier tape prepared from PET, APET and other materials. The stamping carrier tape is mainly prepared from paper materials or PE composite materials.

PC materials are characterized by high mechanical strength, good transparency, good dimensional stability and good heat resistance. The mechanical strength of the PS material is lower than that of the PC material, so sometimes the ABS material is made into a three-layer composite sheet to improve the tensile strength of the carrier tape. The mechanical strength of the PET material is close to that of the PC, but due to the crystalline material, the dimensional stability is poor.

Extended reading “How to deal with the carrier tape and the cover tape sealing crack”