Many customers looking for Plastic Anti-static IC shipping tubes are very focused on if the tube is beautiful. They will think if the IC tube looks terrible, the quality will not be outstanding, so the appearance of the IC packaging tube gives people a critical first impression. So what are the appearance factors that affect IC packaging tubes?

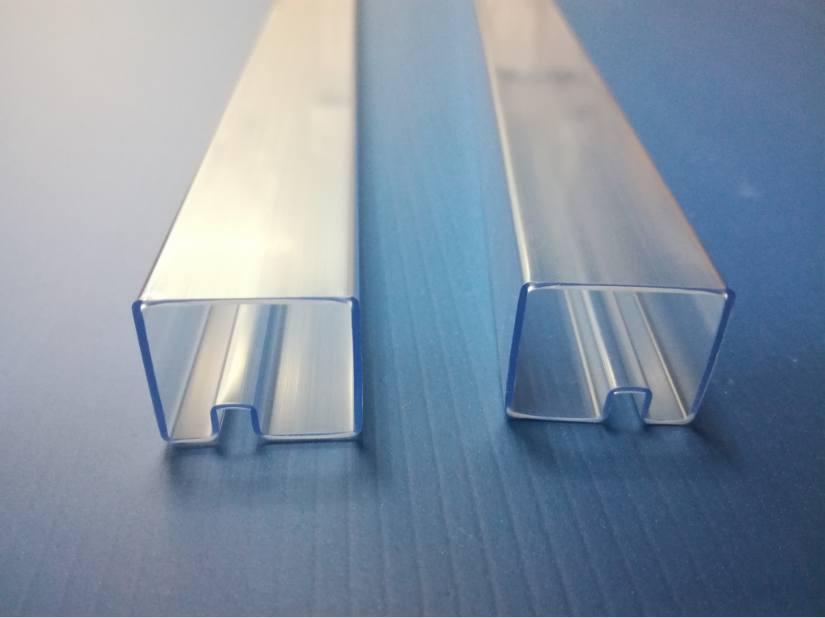

Firstly, the choice of raw materials. The raw materials used in the production of IC shipping tubes are PVC, HIPS, PET, and ABS, among which PVC and HIPS are mostly. The surface of the tube made of PVC material is transparent and blue, and the HIPS material is more transparent.

For the selection of raw materials, please refer to the article “Introduction to IC Packaging Tubes and Materials”.

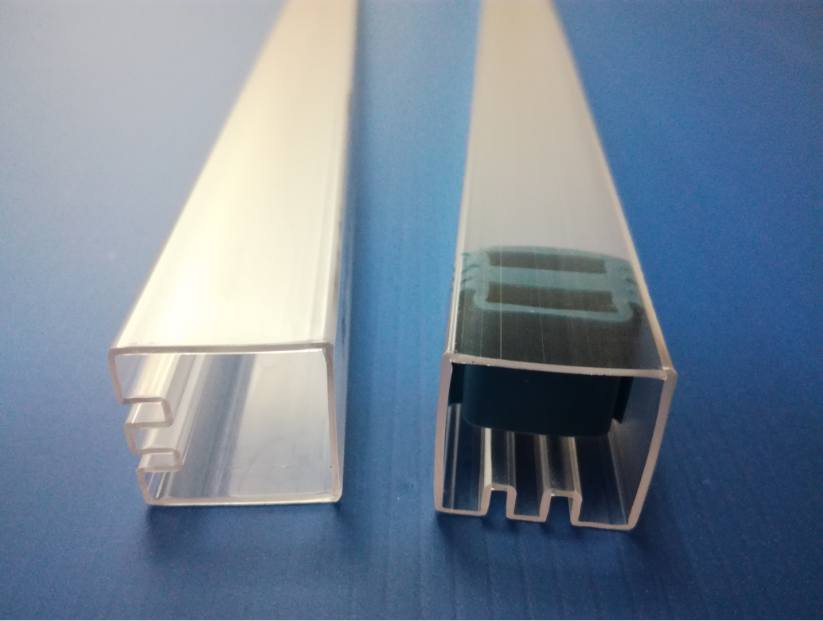

Second, the quality of raw materials. The surface of the IC shipping tube made of suitable raw materials is transparent blue, and the gloss and transparency are excellent. It is easy to check the quality of the parts inside through the transparent wall; the surface of the IC tube produced by the defective raw materials is pale and light yellow. The color, the gloss transparency is not good. It is not easy to check the quality of the parts inside through the fuzzy wall, which is caused by the addition of miscellaneous materials, recycled materials, and waste materials.

Extended reading “How to identify high quality ic packaging tube”

Third, the production process. The exquisite production process produces tubes with no spots, no burrs, scratches when cutting, and uniform wall thickness. Each of these packing tubes can meet appearance standards.

For the production process, please refer to the content “Production Process of IC Packaging Tubes”